High-Efficiency Screw Type Air Compressors

Product Overview

Picture this: an innovative structure that not only looks sleek but also functions with exceptional efficiency. The screw type air compressor embodies just that. With its compact design, it not only minimizes energy consumption but also operates quietly, blending seamlessly into any environment. These compressors are renowned for their longevity and represent smart, eco-friendly solutions that are increasingly vital in today’s industrial landscape. They find applications in various sectors such as metallurgy, machinery, chemicals, mining, and the electric power industry. Serving as optimal air source equipment, they are indeed the backbone of many operations.

Advantages of Our Air Compressors

Advanced Engineering

Harnessing the sophistication of third-generation rotor technology, these compressors integrate a streamlined intake control system. The result? Superior performance that rivals the best in the market. Think of it as a finely tuned sports car; it’s all about precision engineering delivering maximum output.

Efficient Oil and Gas Separation

The way these compressors manage oil and gas separation is nothing short of revolutionary. With efficient centrifugal separation, they dramatically reduce the gas oil content. This leads to an increase in the lifespan of the tube and core components. In practice, this means fewer breakdowns and more uptime—just what every factory manager dreams of!

Low Noise Operation

Quieter than a whisper, our compressors feature a highly efficient, low-noise suction fan. By maximizing dynamic pressure, they enhance heat transfer while keeping noise levels to a minimum. Imagine working in an environment where background noise is almost non-existent—this is the peace of mind our compressors afford you.

Automatic Cooling System

The integrated automatic water-cooling system is engineered for large air compressors. It optimizes operational efficiency by maintaining optimal temperatures. Think of it as a cooling system for a marathon runner, ensuring they never overheat during a race.

User-Friendly Diagnostics

Equipped with an intuitive fault diagnosis system, our control panel allows for effortless operation and real-time monitoring. It’s like having a personal assistant, always on hand to check system performance without the fuss.

Convenient Maintenance

No more acrobatics to reach the inner workings of your compressor! Our removable door design ensures that maintenance and service are convenient and accessible, saving you both time and hassle.

Real-Time Monitoring

Advanced micro-electronic processing enables meticulous monitoring of temperature, pressure, and other vital parameters. This ensures optimal performance, akin to a pilot constantly checking instruments in a cockpit.

Explore More of Our Offerings

Beyond air compressors, our company specializes in a vast array of industrial products. From agricultural gearboxes and power output shafts to hydraulic couplings and sprockets, we offer high-quality products at competitive prices. Exceptional customer service is our hallmark. We also welcome customization requests based on your specific drawings and samples—think of us as a tailor for industrial components!

Frequently Asked Questions

What industries utilize screw type air compressors?

Screw type air compressors are extensively utilized in metallurgy, machinery, chemicals, mining, and electric power industries. They’re like the Swiss Army knife of industrial equipment—versatile and reliable across various applications.

What are the advantages of a low-noise suction fan?

A low-noise suction fan enhances the overall operational environment by minimizing noise pollution while maintaining high efficiency. It’s all about keeping the workplace pleasant while you grind through tasks!

How does the automatic water-cooling system work?

The automatic water-cooling system plays a crucial role in regulating the temperature of large air compressors. This ensures that they operate at peak efficiency, much like a well-oiled machine in a bustling factory.

Can I customize the air compressor based on my specifications?

Absolutely! We welcome customization requests. Just provide your drawings and samples, and we’ll create tailored solutions that align perfectly with your needs.

What other products do you offer?

In addition to air compressors, we supply a variety of industrial products, including agricultural gearboxes, hydraulic couplings, and more. It’s a comprehensive catalog designed to meet diverse industrial needs.

Performance Characteristics of Packing Compressors

Packing compressors are critical components in various industrial applications, renowned for their efficiency and versatility. Here are the primary performance characteristics of packing compressors, explained in detail:

- High Efficiency: Packing compressors are designed to deliver maximum output with minimal energy consumption. They utilize advanced engineering to compress gases effectively, ensuring optimal performance in various applications. For instance, a food packaging facility can use these compressors to minimize energy costs while maintaining production speed.

- Durability: Constructed from robust materials, packing compressors exhibit remarkable durability. Their design allows them to withstand demanding conditions, making them ideal for heavy-duty applications. Imagine a compressor working continuously in a mining operation without a hitch.

- Low Maintenance: With fewer moving parts compared to traditional compressors, packing compressors require less maintenance. This feature not only reduces operational costs but also minimizes downtime, keeping the production line rolling.

However, it’s essential to note that while these compressors excel in certain conditions, they may not perform as well in extreme environments, such as those found in high-temperature applications. This contradiction prompts a closer look at the surrounding operating conditions. Adapting these compressors with appropriate insulation or cooling solutions can mitigate potential issues, allowing for expanded operational ranges.

- Versatility: Packing compressors can handle a wide range of gases and applications. This adaptability makes them suitable for diverse industries, from food packaging to industrial manufacturing. A classic example would be their role in creating controlled atmospheres for food storage, preventing spoilage.

- Noise Reduction: Many modern packing compressors are engineered with noise-reducing features. This attribute is essential for applications where noise levels need to be kept to a minimum, such as hospitals and research facilities.

Types and Characteristics of Packing Compressors

Packing compressors come in various types, each tailored to specific applications and operational needs. Understanding these types and their characteristics is vital for selecting the appropriate compressor.

- Reciprocating Compressors: These compressors utilize pistons to compress gases. They are known for their high-pressure capabilities and are commonly used in industries requiring substantial pressure outputs, like automotive.

- Rotary Compressors: Featuring rotating elements, these compressors provide continuous gas compression. They are favored for their compact design and efficiency in moderate pressure scenarios. A typical use case might be in air conditioning systems.

- Screw Compressors: Utilizing twin screws for compression, these compressors are efficient and reliable. They are ideal for a broad range of applications, offering consistent pressure and flow rates. This makes them perfect for large industrial plants where steady airflow is crucial.

Advantages of Packing Compressors Made of Different Materials

The material composition of packing compressors significantly influences their performance, durability, and suitability for specific applications.

- Aluminum: Lightweight and efficient, aluminum packing compressors offer excellent thermal conductivity. They are ideal for applications that require rapid temperature regulation, such as in refrigeration systems.

- Stainless Steel: Renowned for its corrosion resistance, stainless steel is the material of choice for packing compressors used in food and pharmaceutical industries. Its durability ensures longevity even in harsh environments, protecting sensitive applications.

- Cast Iron: Known for its strength and vibration-dampening properties, cast iron packing compressors are perfect for heavy-duty applications where reliability is paramount. Picture these in a bustling manufacturing plant, tirelessly working without complaint.

Applications of Packing Compressors

Packing compressors find extensive use across various sectors, reflecting their value and significance in numerous applications.

- Vacuum Packaging: In vacuum packaging, packing compressors are crucial for removing air from packages, thereby prolonging shelf life and maintaining product quality. Think about how a fresh bag of coffee stays aromatic because of this technology.

- Modified Atmosphere Packaging: These compressors help create a specific gas composition within the packaging, which is essential for preserving freshness in perishable products. It’s a game changer in the food industry.

- Sealing and Closing Machines: Packing compressors are integral in sealing machines, ensuring airtight seals that protect products from contamination. This is vital for everything from pharmaceuticals to electronics.

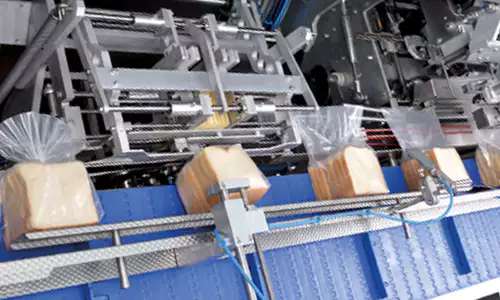

- Food Packaging Automation: Automated food packaging systems rely on packing compressors to enhance speed and efficiency in packaging operations. They streamline processes, saving both time and money.

- Industrial Packaging Systems: In various industrial settings, packing compressors provide the necessary compression for efficient packaging processes. This versatility allows them to adapt to numerous production lines.

Future Development Trends and Opportunities

The future of packing compressors holds exciting prospects as technological advancements pave the way for innovation.

- Smart Technology Integration: The incorporation of IoT technology will enable real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing unexpected failures.

- Eco-friendly Solutions: With increasing environmental concerns, the development of energy-efficient packing compressors will gain traction, focusing on reducing carbon footprints. It’s high time we go green!

- Enhanced Customization: As industries evolve, the demand for customized packing compressors tailored to specific operational needs will rise. Flexibility will be key in meeting diverse requirements.

Choosing a Suitable Packing Compressor

Selecting the right packing compressor involves careful consideration of several key factors:

- Application Requirements: Identify the specific needs of your application, such as pressure and flow rate requirements. It’s like choosing the right tool for a job—precision matters.

- Flow Rate and Pressure: Ensure that the compressor can deliver the necessary flow rate and pressure for optimal performance. Too little pressure can slow down processes.

- Energy Efficiency: Look for compressors that are designed for energy efficiency to minimize operational costs. It pays to save in the long run!

- Noise Level: Consider the noise levels produced by the compressor, especially in environments where noise reduction is critical. Nobody wants to work in a noisy environment!

- Clean Air Requirements: Ensure the compressor meets any necessary clean air standards, especially for food and pharmaceutical applications. It’s about safety and quality.

- Compliance with Standards: The compressor should comply with industry standards to ensure safety and reliability. Being compliant is not just a checklist item; it’s a necessity.

Conclusion

In summary, packing compressors are vital components in various industrial applications, offering numerous benefits including efficiency, durability, and versatility. By understanding their performance characteristics, types, and applications, you can significantly enhance your decision-making when selecting the right compressor. As technology continues to advance, the future of packing compressors promises innovations that will further improve their functionality and environmental impact. The promise of smarter, greener solutions is on the horizon, setting the stage for the next generation of packing compressors.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.