High-Efficiency Rotary Screw Air Compressors

Product Overview

Our rotary screw air compressors represent a sophisticated engineering feat, blending a sleek, compact design with unparalleled functionality. These compressors are not just about looks; they are crafted for high efficiency, minimal energy consumption, and remarkably low noise levels, making them the go-to choice for those who care about the environment and their energy bills. Think of them as the silent warriors of air compression, quietly powering various sectors like metallurgy, machinery, chemicals, mining, and electric power with reliability and finesse. With a reputation for durability and longevity, these machines serve as steadfast air source equipment across diverse applications.

Key Advantages

1. Advanced Rotor Technology

Leveraging the third generation of advanced rotor technology, our compressors are engineered to ensure precise intake control. This means superior performance that feels like a well-oiled machine, where every component works in harmony.

2. Efficient Oil and Gas Separation

Equipped with an efficient centrifugal separator, our compressors minimize gas oil content significantly. This not only enhances longevity for tubing and core components but also keeps maintenance costs down, which is a win-win situation.

3. Low Noise Operation

Designed to utilize dynamic pressure effectively, our low-noise suction fan doesn’t just reduce operational sound; it enhances heat transfer, making your work environment far more pleasant. Imagine being able to chat comfortably even while the compressor hums in the background.

4. Automatic Cooling System

Each of our compressors comes with a sophisticated automatic water-cooling system, especially tailored for larger models. This ensures that they perform at their best, whether in a bustling factory or a quiet workshop.

5. User-Friendly Diagnostic Features

Our intuitive control panel is not just for show; it features a fault diagnosis system that simplifies the operation and monitoring of compressor performance. It’s like having a personal assistant for your equipment!

6. Convenient Maintenance

With removable access doors, maintaining your compressor becomes as easy as pie. Quick servicing means reduced downtime, letting you get back to what you do best without unnecessary delays.

7. Enhanced Monitoring Technology

The incorporation of micro-electronic processing technology allows for critical parameters such as temperature and pressure to be monitored closely, thus enhancing operational safety. In a field where precision is key, this feature feels like having an extra layer of protection.

Other Products and Services

In addition to our high-quality rotary screw air compressors, we proudly offer a diverse array of industrial products. Our inventory is packed with essentials such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We take pride in offering preferential pricing and attentive customer service. Customization options are available based on drawings and samples provided by our clients, ensuring a tailored approach to meet your specific needs.

Frequently Asked Questions

1. What industries can benefit from using rotary screw air compressors?

These compressors are a boon for various industries including metallurgy, machinery, chemicals, mining, and electric power. They are the backbone of operations that require reliable air sources.

2. How does the advanced rotor technology improve compressor performance?

The advanced rotor technology enhances the efficiency of intake control, leading to improved performance and energy savings. It’s like upgrading from a bicycle to a high-speed motorcycle!

3. Are these compressors noisy during operation?

Our compressors are designed with a low-noise operation feature, ensuring they run quietly. You won’t have to shout to make yourself heard over the din!

4. What maintenance is required for these compressors?

With removable doors for easy access, maintenance is straightforward and manageable. It’s all about keeping things simple and efficient.

5. Can I customize the compressor according to my specifications?

Absolutely! We welcome customers to customize their compressors based on provided drawings and samples, ensuring that you get a solution tailored just for your needs.

Performance Characteristics of Packing Compressors

Packing compressors are crucial in various industrial settings, known for their efficiency and versatility. Let’s break down their primary performance characteristics:

- High Efficiency: Designed to deliver maximum output with minimal energy consumption, packing compressors utilize cutting-edge engineering to compress gases effectively. Picture this: a compressor that works smarter, not harder, saving you both energy and money.

- Durability: Made from robust materials, packing compressors are built to last. They can withstand demanding conditions with ease, making them perfect for heavy-duty applications. Think of them as the sturdy workhorses of the industrial world.

- Low Maintenance: With fewer moving parts compared to traditional compressors, packing compressors require less maintenance. This feature reduces operational costs and minimizes downtime, keeping your workflows uninterrupted.

- Versatility: Capable of handling a wide range of gases and applications, packing compressors are suitable for diverse industries, from food packaging to industrial manufacturing. They adapt like a chameleon to fit various operational needs.

- Noise Reduction: Many modern packing compressors are engineered with noise-reducing features. In environments where noise levels need to be controlled, these compressors are a breath of fresh air.

Types and Characteristics of Packing Compressors

Packing compressors come in various types, each tailored to specific applications. Understanding these types and their characteristics is crucial for selecting the right compressor:

- Reciprocating Compressors: Utilizing pistons, these compressors excel in high-pressure applications. They are often seen in industries requiring significant pressure outputs, like oil and gas.

- Rotary Compressors: Featuring rotating elements, these compressors provide continuous gas compression, making them ideal for moderate pressure scenarios. Think of them as the smooth operators in an industrial setting.

- Screw Compressors: Using twin screws for compression, these compressors are both efficient and reliable, perfect for applications requiring consistent pressure and flow rates. They are the reliable friends that never let you down.

Advantages of Packing Compressors Made of Different Materials

The material composition of packing compressors significantly affects their performance and durability. Here’s a look at the advantages of different materials:

- Aluminum: Lightweight and efficient, aluminum packing compressors excel in thermal conductivity, making them ideal for applications needing rapid temperature regulation. They are like the sprinters in the compressor world!

- Stainless Steel: Known for its corrosion resistance, stainless steel is the go-to choice in food and pharmaceutical industries. Its durability ensures longevity even when the going gets tough.

- Cast Iron: Strong and with excellent vibration-dampening properties, cast iron packing compressors are perfect for heavy-duty applications. They are the tanks in a world of lightweight competitors.

Applications of Packing Compressors

Packing compressors find extensive use across various sectors. Their significance in numerous applications cannot be overstated:

- Vacuum Packaging: These compressors are crucial for removing air from packages, prolonging shelf life and maintaining product quality. They keep your food fresh, just like a time capsule!

- Modified Atmosphere Packaging: Packing compressors help create specific gas compositions, essential for preserving freshness in perishable products. It’s all about keeping things just the way nature intended.

- Sealing and Closing Machines: Integral in sealing machines, packing compressors ensure airtight seals that protect products from contamination. Think of them as the guardians of product integrity.

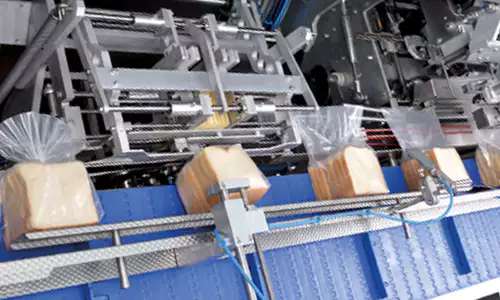

- Food Packaging Automation: Automated food packaging systems depend on packing compressors to enhance speed and efficiency in operations. They streamline processes like a well-rehearsed performance.

- Industrial Packaging Systems: In various industrial settings, packing compressors provide the necessary compression for efficient packaging. They are the unsung heroes behind the scenes.

Future Development Trends and Opportunities

The future of packing compressors is bright, driven by technological advancements that pave the way for innovation:

- Smart Technology Integration: The incorporation of IoT technology will enable real-time monitoring and predictive maintenance, enhancing operational efficiency. Imagine a compressor that can tell you when it needs a tune-up!

- Eco-friendly Solutions: As environmental concerns rise, the development of energy-efficient packing compressors will gain traction, focusing on reducing carbon footprints. Sustainability is not just a trend; it’s a necessity.

- Enhanced Customization: As industries evolve, the demand for customized packing compressors tailored to specific operational needs will increase. It’s all about finding the perfect fit for your unique requirements.

Choosing a Suitable Packing Compressor

Selecting the right packing compressor involves careful consideration of several key factors:

- Application Requirements: Identify the specific needs of your application, such as pressure and flow rate requirements. You don’t want to end up with a compressor that’s overkill or underwhelming!

- Flow Rate and Pressure: Ensure that the compressor can deliver the necessary flow rate and pressure for optimal performance. Think of this as finding the right horsepower for your vehicle.

- Energy Efficiency: Look for compressors designed for energy efficiency to minimize operational costs. It’s like having a fuel-efficient car compared to a gas guzzler.

- Noise Level: Consider the noise levels produced by the compressor, especially in environments where noise reduction is critical. Keep peace and productivity in the workplace!

- Clean Air Requirements: Ensure the compressor meets necessary clean air standards, particularly for food and pharmaceutical applications. Hygiene is paramount!

- Compliance with Standards: The compressor should comply with industry standards for safety and reliability. It’s the assurance that what you’re working with meets all the regulations.

Conclusion

In conclusion, packing compressors are vital components in various industrial applications, offering numerous benefits such as efficiency, durability, and versatility. Recognizing their performance characteristics, types, and applications can greatly enhance your decision-making process when selecting the right compressor. As technology continues to advance, the future of packing compressors promises innovations that will further improve their functionality and reduce their environmental impact.

Author: Dream

All the content of this page is sourced from the Internet, and it serves as a reference for product selection. Our products are replacement parts and not original spare parts; we do not hold the original trademarks of the content. Our products are tailored for after-sales replacement parts and are not original spare parts. These replacement parts can perfectly adapt to the original spare parts. For original spare parts, please contact the original factory for purchase.