High-Quality Centrifugal Air Compressors

Product Overview

Presenting our cutting-edge Centrifugal Air Compressors, engineered to offer unparalleled performance and robust reliability across a multitude of industrial applications. These compressors are like the heart of a machine, pumping vital air efficiently into systems that demand high precision. Designed with meticulous attention to detail, they operate seamlessly under even the most arduous conditions, making them the go-to choice for industries where failure is not an option.

Product Features

Optimal Performance

Our centrifugal air compressors are meticulously tailored for optimal performance, ensuring a robust output that meets the intricate demands of modern industrial operations. Think of them as the high-performance athletes of the compressor world; they maintain consistent airflow while minimizing energy consumption, saving you both time and money. For instance, in a manufacturing plant where air supply is crucial for assembly lines, these compressors keep operations running smoothly without breaking a sweat.

Durability and Reliability

Built from high-quality materials, our compressors boast remarkable durability that ensures longevity and reliable performance. Just like a trusty old workhorse, they are suitable for a variety of applications, even when faced with extreme temperature fluctuations. Picture a construction site in the blazing sun or a frigid winter; our compressors stand firm, delivering unmatched service without compromise.

Product Specifications

- Voltage Options: 380V/50HZ/3Phase, 400V/50HZ/3P, 415V/50HZ/3P, 220V/60HZ/3P, 380V/60HZ/3P, 440V/60HZ/3P

- Temperature Range: Operates efficiently in environments from 1-45 ºC (33.8ºF-113ºF)

- Minimum Order Quantity: 1 PCS

Exceptional After-Sales Service

We take immense pride in delivering unparalleled after-sales service that ensures your experience with our products is smooth and satisfying. Our dedicated team is always ready to assist, whether you have inquiries or require support post-purchase. It’s like having a safety net; we’re here to catch you if you fall.

Related Products

Beyond our high-quality centrifugal air compressors, we also supply a diverse array of industrial products, including:

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Hydraulic Couplings

- Worm Gear Reducers

- Racks

- Roller Chains

- Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

We invite our customers to customize orders tailored to their specific drawings and samples, ensuring that you receive exactly what you need at preferential prices, accompanied by thoughtful service. It’s all about making sure you get the right fit, like a tailored suit.

Frequently Asked Questions

| 1. What trade terms do you provide? | We offer trade terms including CIF, CFR, FOB, and Ex-Works, with transactions in Dollars, Euros, and RMB. |

| 2. What is the typical delivery time? | The standard delivery time is 30-40 days after order confirmation and receipt of payment for standard compressors. Non-standard requirements are discussed on a case-by-case basis. |

| 3. Can your compressors operate in high-temperature environments? | Absolutely! Our compressors are designed to function in high-temperature conditions, and they have successfully been implemented in countries facing extreme summer heat, such as Iraq and Saudi Arabia. They don’t just survive; they thrive. |

| 4. What is the minimum order requirement? | The minimum order quantity stands at just 1 piece. |

| 5. What voltage options are available for the compressors? | The compressors come with various voltage options, such as 380V/50HZ/3Phase and others, tailored to meet customer specifications. |

Performance Characteristics of Packing Compressors

Packing compressors play a pivotal role in various industrial applications, known for their efficiency and adaptability. Here are the primary performance characteristics that stand out:

- High Efficiency: Designed for maximum output with minimal energy consumption, packing compressors utilize advanced engineering to compress gases effectively, ensuring optimal performance in diverse applications. Imagine powering a city with just a fraction of the energy—this is what these compressors can achieve.

- Durability: Constructed from robust materials, packing compressors exhibit remarkable durability. Their design allows them to withstand demanding conditions, making them perfect for heavy-duty applications. Think of them like the trusty SUVs of the compressor world—built to last and tackle tough terrains.

- Low Maintenance: With fewer moving parts compared to traditional compressors, they require less maintenance. This feature not only reduces operational costs but also minimizes downtime. Less fuss, more function!

- Versatility: Packing compressors can handle a wide range of gases and applications. This adaptability makes them suitable for various industries, from food packaging to industrial manufacturing. They’re like the Swiss Army knives of compressors—always ready for whatever task comes their way.

- Noise Reduction: Many modern packing compressors are engineered with noise-reducing features, essential for applications where noise levels need to be kept to a minimum.

Types and Characteristics of Packing Compressors

Packing compressors come in various types, each tailored to specific applications and operational needs. Understanding these types and their characteristics is vital for selecting the appropriate compressor.

- Reciprocating Compressors: Utilizing pistons to compress gases, these compressors are known for their high-pressure capabilities and are commonly used in industries requiring substantial pressure outputs.

- Rotary Compressors: Featuring rotating elements, these compressors provide continuous gas compression. They are favored for their compact design and efficiency in moderate pressure scenarios.

- Screw Compressors: Utilizing twin screws for compression, these compressors are efficient and reliable, ideal for a broad range of applications, offering consistent pressure and flow rates.

Advantages of Packing Compressors Made of Different Materials

The material composition of packing compressors significantly influences their performance, durability, and suitability for specific applications:

- Aluminum: Lightweight and efficient, aluminum packing compressors offer excellent thermal conductivity, making them ideal for applications that require rapid temperature regulation.

- Stainless Steel: Renowned for its corrosion resistance, stainless steel is the material of choice for packing compressors used in food and pharmaceutical industries. Its durability ensures longevity even in harsh environments.

- Cast Iron: Known for its strength and vibration-dampening properties, cast iron packing compressors are perfect for heavy-duty applications where reliability is paramount.

Applications of Packing Compressors

Packing compressors find extensive use across various sectors, reflecting their value and significance in numerous applications:

- Vacuum Packaging: In vacuum packaging, packing compressors are crucial for removing air from packages, thereby prolonging shelf life and maintaining product quality.

- Modified Atmosphere Packaging: These compressors help create a specific gas composition within the packaging, essential for preserving freshness in perishable products.

- Sealing and Closing Machines: Packing compressors are integral in sealing machines, ensuring airtight seals that protect products from contamination.

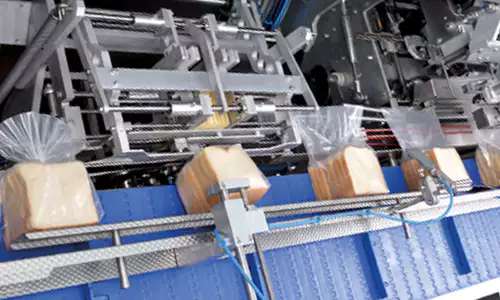

- Food Packaging Automation: Automated food packaging systems rely on packing compressors to enhance speed and efficiency in packaging operations.

- Industrial Packaging Systems: In various industrial settings, packing compressors provide the necessary compression for efficient packaging processes.

Future Development Trends and Opportunities

The future of packing compressors is full of exciting prospects as technological advancements pave the way for innovation:

- Smart Technology Integration: The incorporation of IoT technology will enable real-time monitoring and predictive maintenance, enhancing operational efficiency. This is like giving your compressor a brain—smart decision-making at your fingertips!

- Eco-friendly Solutions: With increasing environmental concerns, the development of energy-efficient packing compressors will gain traction, focusing on reducing carbon footprints. It’s not just about performance anymore; it’s about preserving our planet too.

- Enhanced Customization: As industries evolve, the demand for customized packing compressors tailored to specific operational needs will rise. It’s all about getting the right fit, so no more one-size-fits-all solutions.

Choosing a Suitable Packing Compressor

Choosing the right packing compressor involves careful consideration of several key factors:

- Application Requirements: Identify the specific needs of your application, such as pressure and flow rate requirements.

- Flow Rate and Pressure: Ensure that the compressor can deliver the necessary flow rate and pressure for optimal performance.

- Energy Efficiency: Look for compressors that are designed for energy efficiency to minimize operational costs.

- Noise Level: Consider the noise levels produced by the compressor, especially in environments where noise reduction is critical.

- Clean Air Requirements: Ensure the compressor meets any necessary clean air standards, especially for food and pharmaceutical applications.

- Compliance with Standards: The compressor should comply with industry standards to ensure safety and reliability. This is crucial for avoiding any hiccups down the line.

Conclusion

In conclusion, packing compressors are vital components in a variety of industrial applications, offering numerous benefits including efficiency, durability, and versatility. These compressors are not just machines; they are the silent workhorses that support industries around the clock. Understanding their performance characteristics, types, and applications can significantly enhance decision-making when selecting the right compressor. As technology continues to advance, the future of packing compressors promises exciting innovations that will further improve their functionality and environmental impact. It’s a bright future ahead!

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection. Our products are replacement parts and not original spare parts; we are not the holders of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory for purchase. If you want to buy original spare parts, please contact the original supplier for purchase.