Air Compressors: Optimal Solutions for Your Industrial Needs

Introduction to Our Premium Air Compressors

Discover the pinnacle of air compression technology with our China Best Cooling Air Compressors. Designed to operate seamlessly for an impressive duration of 12 months, these units exemplify the CHINAMFG standard in export packing. Just like a reliable partner in a tough race, our compressors stand by you, delivering efficiency and reliability in every task, ensuring that your operations run as smoothly as a well-oiled machine.

Product Features

High Performance

Our air compressors are engineered for superior performance. They provide consistent and robust airflow, making them suitable for both industrial and commercial use. Picture this: a workshop bustling with activity, and in the background, our compressors hum along, supporting every tool that needs a power boost. This is not just performance; it’s a commitment to excellence.

Durability and Longevity

With a construction that prioritizes durability, these compressors are built to withstand rigorous operational demands, ensuring longevity and sustained performance over time. Think of it as investing in a sturdy pair of boots for a long trek—reliable, hard-wearing, and ready for the challenges of the road ahead.

Why Choose Our Air Compressors?

Choosing our air compressors means opting for quality without compromise. We focus on utilizing the finest materials and innovative engineering to produce compressors that not only meet but exceed industry standards. Additionally, our products are offered at preferential prices, allowing you to achieve high efficiency without breaking the bank. It’s like finding a diamond in the rough—exceptional quality at an accessible price.

Explore Our Diverse Range of Products

In addition to air compressors, our company specializes in an extensive selection of industrial products. We offer agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our commitment to high-quality products, customer-centric services, and customization options for drawings and samples ensures that you receive exactly what you need for your operations. Imagine gearing up a complex machine; each component must fit perfectly to create harmony in performance.

Frequently Asked Questions

- What is the warranty period for your air compressors? Our air compressors come with a warranty period of 12 months, ensuring peace of mind for our customers.

- Can I customize my air compressor according to my specifications? Yes, we welcome customization requests based on drawings and samples to meet your specific needs.

- Are your air compressors suitable for both industrial and commercial uses? Absolutely! Our compressors are versatile and designed to cater to a wide range of applications.

- What other products does your company offer? We supply various industrial products including agricultural gearboxes, hydraulic couplings, and more.

- How can I contact you for more information? Please visit our website or reach out to our sales team for any inquiries regarding our products.

Performance Characteristics of Packing Compressors

Packing compressors are critical components in various industrial applications, renowned for their efficiency and versatility. Here are the primary performance characteristics of packing compressors, explained in detail:

- High Efficiency: Packing compressors are designed to deliver maximum output with minimal energy consumption. They utilize advanced engineering to compress gases effectively, ensuring optimal performance in various applications. Much like athletes training for peak performance, these compressors are built to excel.

- Durability: Constructed from robust materials, packing compressors exhibit remarkable durability. Their design allows them to withstand demanding conditions, making them ideal for heavy-duty applications. In fact, think of them as the workhorses of the industry—sturdy and dependable.

- Low Maintenance: With fewer moving parts compared to traditional compressors, packing compressors require less maintenance. This feature not only reduces operational costs but also minimizes downtime, which is every manager’s dream.

- Versatility: Packing compressors can handle a wide range of gases and applications. This adaptability makes them suitable for diverse industries, from food packaging to industrial manufacturing.

- Noise Reduction: Many modern packing compressors are engineered with noise-reducing features. This attribute is essential for applications where noise levels need to be kept to a minimum. Just imagine a quiet workspace, where the only sound is the gentle hum of efficient machinery.

Types and Characteristics of Packing Compressors

Packing compressors come in various types, each tailored to specific applications and operational needs. Understanding these types and their characteristics is vital for selecting the appropriate compressor.

- Reciprocating Compressors: These compressors utilize pistons to compress gases. They are known for their high-pressure capabilities and are commonly used in industries requiring substantial pressure outputs. Consider the dynamic world of automotive manufacturing—these compressors are often at the heart of the action.

- Rotary Compressors: Featuring rotating elements, these compressors provide continuous gas compression. They are favored for their compact design and efficiency in moderate pressure scenarios, much like a well-oiled bicycle, providing smooth rides with less effort.

- Screw Compressors: Utilizing twin screws for compression, these compressors are efficient and reliable. They are ideal for a broad range of applications, offering consistent pressure and flow rates. Picture a factory floor where every screw is turning, driving the entire operation forward.

Advantages of Packing Compressors Made of Different Materials

The material composition of packing compressors significantly influences their performance, durability, and suitability for specific applications.

- Aluminum: Lightweight and efficient, aluminum packing compressors offer excellent thermal conductivity. They are ideal for applications that require rapid temperature regulation, perfect for industries where precision is key.

- Stainless Steel: Renowned for its corrosion resistance, stainless steel is the material of choice for packing compressors used in food and pharmaceutical industries. Its durability ensures longevity even in harsh environments. Think of it as the superhero of materials, saving the day by resisting wear and tear.

- Cast Iron: Known for its strength and vibration-dampening properties, cast iron packing compressors are perfect for heavy-duty applications where reliability is paramount. Just like a sturdy bridge, they provide unwavering support for demanding tasks.

Applications of Packing Compressors

Packing compressors find extensive use across various sectors, reflecting their value and significance in numerous applications.

- Vacuum Packaging: In vacuum packaging, packing compressors are crucial for removing air from packages, thereby prolonging shelf life and maintaining product quality. It’s like wrapping a gift; the right packing ensures it stays fresh and intact.

- Modified Atmosphere Packaging: These compressors help create a specific gas composition within the packaging, which is essential for preserving freshness in perishable products. Imagine the fruits and vegetables in your fridge—these compressors play a role in keeping them crisp and vibrant.

- Sealing and Closing Machines: Packing compressors are integral in sealing machines, ensuring airtight seals that protect products from contamination. Just like a tight lid on a jar, they keep the contents safe and sound.

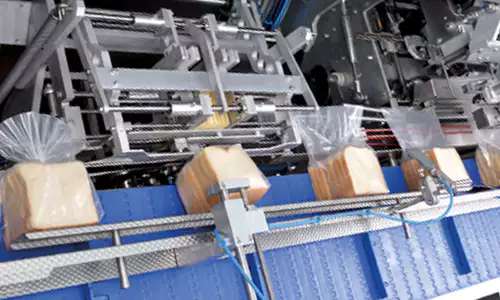

- Food Packaging Automation: Automated food packaging systems rely on packing compressors to enhance speed and efficiency in packaging operations. Picture a busy conveyor belt where every item is expertly packed, thanks to these compressors.

- Industrial Packaging Systems: In various industrial settings, packing compressors provide the necessary compression for efficient packaging processes. They are the unsung heroes behind the scenes making sure everything runs smoothly.

Future Development Trends and Opportunities

The future of packing compressors holds exciting prospects as technological advancements pave the way for innovation.

- Smart Technology Integration: The incorporation of IoT technology will enable real-time monitoring and predictive maintenance, enhancing operational efficiency. Picture a world where your compressor sends you a text when it needs attention—now, that’s smart!

- Eco-friendly Solutions: With increasing environmental concerns, the development of energy-efficient packing compressors will gain traction, focusing on reducing carbon footprints. It’s like turning over a new leaf, embracing sustainability for a greener future.

- Enhanced Customization: As industries evolve, the demand for customized packing compressors tailored to specific operational needs will rise. Think of it as a bespoke suit; it fits perfectly and looks sharp!

Choosing a Suitable Packing Compressor

Selecting the right packing compressor involves careful consideration of several key factors:

- Application Requirements: Identify the specific needs of your application, such as pressure and flow rate requirements. Just like you wouldn’t wear hiking boots to a formal event, you need the right compressor for the job.

- Flow Rate and Pressure: Ensure that the compressor can deliver the necessary flow rate and pressure for optimal performance. The wrong combo could lead to inefficiencies, much like pairing the wrong wine with dinner.

- Energy Efficiency: Look for compressors that are designed for energy efficiency to minimize operational costs. Saving on energy is like putting money back in your pocket!

- Noise Level: Consider the noise levels produced by the compressor, especially in environments where noise reduction is critical. After all, a quiet shop is a happy shop.

- Clean Air Requirements: Ensure the compressor meets any necessary clean air standards, especially for food and pharmaceutical applications. Clean air is the lifeblood of industries that prioritize health and safety.

- Compliance with Standards: The compressor should comply with industry standards to ensure safety and reliability. This is like checking the quality guarantee before making a big purchase.

Conclusion

In summary, packing compressors are vital components in various industrial applications, offering numerous benefits including efficiency, durability, and versatility. Understanding their performance characteristics, types, and applications can significantly enhance decision-making when selecting the right compressor. As technology continues to advance, the future of packing compressors promises innovations that will further improve their functionality and environmental impact. Just remember, choosing the right compressor is not just about performance; it’s about partnering with a reliable ally in your operational journey.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.